- Home

- News & Press

- PRINTING ON MEDICAL TUBING: WHY CHOOSING INKJET PRINTING OR LASER MARKING?

PRINTING ON MEDICAL TUBING: WHY CHOOSING INKJET PRINTING OR LASER MARKING?

29-05-2024

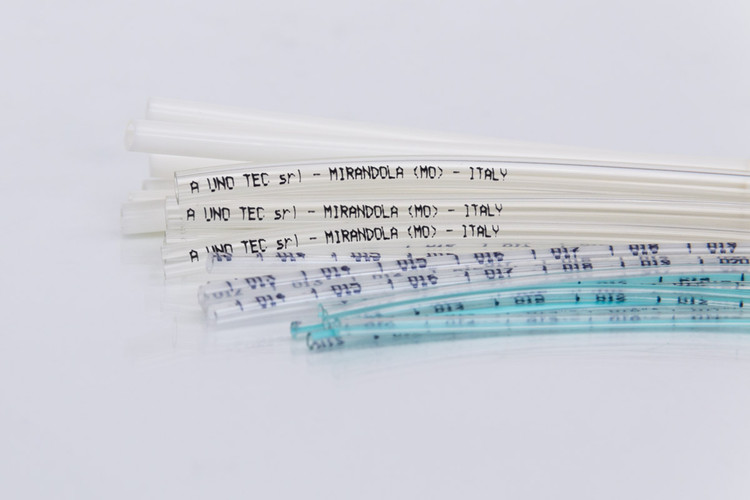

Printing on medical tubing is an important process for their identification and traceability. Pad printing is a commonly used method for marking medical tubing. However, this technique has several limitations that can compromise the quality of products.

Pad printing uses a pre-defined cliché as a printing tool, which greatly limits not only the length of the string to be printed on tubing, but also the possibility of easily changing the information to be printed. It also uses inks that may not be sufficiently resistant to wear and aggressive detergents used in medical environments, compromising quality and legibility of the printed information. Finally, pad printing is less effective on irregular or complex surfaces, which makes it an unsuitable option for certain kind of products.

In the medical field, there are two printing technologies that can overcome these limitations, namely inkjet printing on tubing and laser marking (laser printing on tubing). Although they have different peculiar characteristics, these two types of printing have several advantages in common, including:

- Precise and uniform marking: Inkjet printing and laser marking offer precise, uniform, and high-resolution marking, ensuring optimal legibility of information even on complex surfaces.

- High wear resistance: Inkjet and laser technologies use permanent inks and markings that are resistant to wear, aggressive detergents, and sterilization conditions, ensuring a long product life.

- Marking flexibility: Both technologies offer great flexibility in the choice of the position and content of the marking, allowing you to print codes, logos, text, and other information anywhere on tubing.

The best type of printing for you will depend on your specific needs. When choosing the most suitable technology, it is essential also to consider the color of the liquid that tubing will have to contain and the material of tubing itself, elements closely linked to the characteristics of the product to be made, whether it is a catheter, drainage/aspiration device or tubing kit for blood collection bags. It is therefore important to carefully evaluate your needs to make the best decision and obtain a high-quality finished product.

A UNO TEC has extensive experience in medical tubing printing and marking, know-how that has led us over the years to design specific machines studied for cutting and printing on medical grade tubing.

Do you want to find out how to best manage tubing printing? Contact us to learn more.