- Home

- News & Press

- CATHETER ASSEMBLY: PRECISION AND SAFETY FOR HEALTH

CATHETER ASSEMBLY: PRECISION AND SAFETY FOR HEALTH

11-07-2024

In the medical market, precision and safety are essential parameters, especially when dealing with devices that come into direct contact with the human body. Catheters of various types, infusional, nasogastric, nelaton, suction, are clear examples of medical products whose manufacture requires the utmost attention and expertise.

The production of these devices has unique characteristics that distinguish it from other manufacturing sectors. In addition, it is necessary to have specific technological skills:

- Material knowledge: It is essential to know the properties and characteristics of the materials used to make catheters.

- Processing techniques: Production requires the mastery of different processing techniques, such as extrusion, printing, assembly, punching, and tip forming.

- Quality control: It is essential to implement rigorous quality control protocols to ensure compliance with current regulations and product safety.

- Automation: Automation of production processes is essential to guarantee efficiency, precision, and repeatability.

The correct manufacture of catheters is essential for patient health. In fact, incorrect assembly can lead to serious risks, including:

- Infections: Microbial contamination can lead to serious infections, especially in immunocompromised patients.

- Obstructions: An incorrectly assembled catheter may have obstructions that impede the flow of fluids, causing pain and complications for the patient.

- Trauma: A catheter that is too rigid or has sharp edges can cause tissue trauma during insertion or removal.

Two advanced technologies that play an important role in catheter production are tip forming, graduated tubing scale printing, and punching:

- Tip forming: This technique allows the tip of the catheter to be created with the desired shape and size, ensuring easy insertion and maximum comfort for the patient.

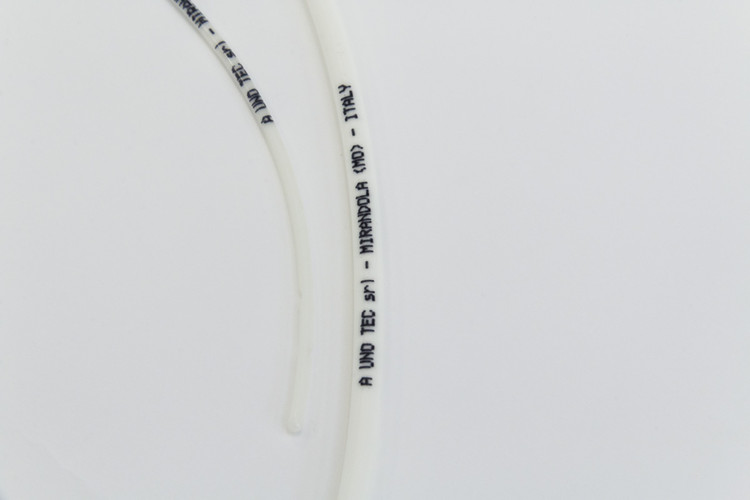

- Graduated tubing scale printing: Printing an accurate graduated scale on the catheter tubing allows medical personnel to accurately measure the depth of insertion and the amount of fluid infused.

- Punching: This technique is a versatile and reliable procedure used to create holes on the catheter.

In conclusion, the production of infusional, nasogastric, nelaton, suction or other types of catheters is a complex and delicate process that requires specific technological skills and cutting-edge machinery. Only through correct manufacturing and the use of advanced technologies it is possible to guarantee a reliable and high-quality finished product.

A UNO TEC has great experience in the design and manufacturing of customized automatic machines for catheter assembly.

Do you want to find out how we can help you in this process? Contact us to learn more.