- Home

- News & Press

- SYSTEMS AND SOLUTIONS FOR MEDICAL TUBING BANDING

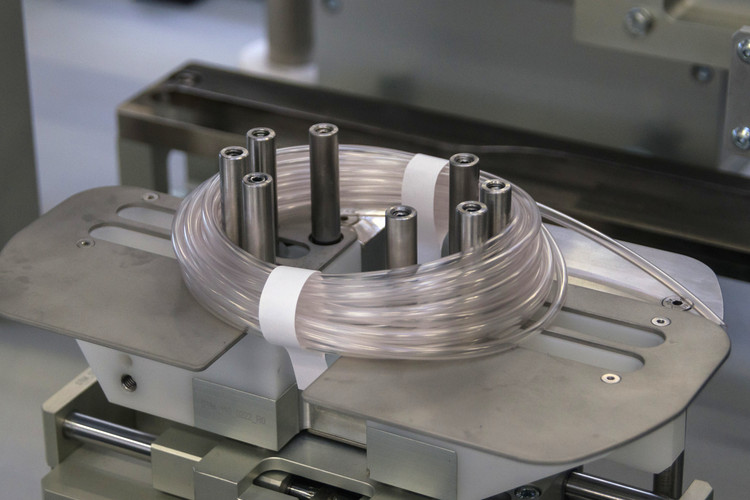

SYSTEMS AND SOLUTIONS FOR MEDICAL TUBING BANDING

24-04-2024

In the medical field, tubing plays a crucial role in various procedures and applications, from drug delivery to assisting in assisted ventilation. Their integrity and functionality are essential for patient safety and well-being. In this context, medical tubing banding systems assume critical importance, directly influencing the product's seal and shape for greater dimensional stability in relation to the blister.

Benefits of a Properly Banded Medical Tubing:

- Ease of Handling: A banded tubing is undoubtedly more convenient and safer to handle in the ward, for any assembly process or packaging of the finished product.

- Stable and Durable Fastening: Banding allows the product to be fastened securely and durably, preventing accidental loosening.

- Improved Aesthetics: Careful and uniform banding gives the product a more polished and professional appearance, increasing the perceived value of the medical device.

Automatic banding offers numerous advantages over manual banding, especially for the production of large volumes of semi-finished products:

- Efficiency and Productivity: Automatic banding systems can perform the banding operation much faster than manual operators, freeing up valuable time and increasing productivity.

- Precision, Uniformity, and Repeatability: Automatic systems guarantee precise and uniform banding, eliminating the risk of human error and ensuring the highest reliability of the final product. In addition, the automatically coiled and banded product allows for greater dimensional stability, making it suitable for packaging.

- Flexibility and Adaptability: Automatic banding systems can be configured and customized to meet specific production needs, with the possibility of integrating various functionalities and options.

- Real-time Monitoring and Control: Production data can be monitored and controlled in real time, allowing processes to be optimized and anomalies to be identified.

- Reduced Operating Costs: Increased efficiency, reduced errors, and decreased labor requirements contribute to lower operating costs in the long run.

Medical tubing banding is a fundamental process to ensure safety, reliability, and aesthetics of medical disposables. The use of automatic medical tubing banding solutions offers numerous advantages in terms of efficiency, precision, flexibility, and control, allowing companies to optimize production processes and manufacture high-quality products.

There are several suitable materials for medical tubing banding. Latex-free cohesive paper is an excellent choice for medical tubing banding in most cases, offering high reliability, safety, and ease of use. Its eco-sustainability also makes it a responsible and environmentally friendly choice. (Read the article on cohesive paper to know more)

However, it is also necessary to evaluate its contraindications and limitations based on the specific needs of the application. In fact, there are alternatives to cohesive paper, such as PE film, for critical applications, greater resistance, and reduced management costs. (Read the article on PE film to know more)

A UNO TEC has extensive experience in medical tubing banding systems and solutions, know-how that has led us over the years to design specific machines studied for banding medical grade tubing.

Curious to know about our tubing banding solutions? Contact us to learn more.